PRODUCTS PARAMETER

Meterials:New zealand Radiata Pine&Larch &Masson pine

Grade:Stuctural Grade

Size:95*4595*65150*77mm Lengh 1000-12000mm

Glue:A Bond phenolic

Feature:Formwork LVL use on LVL Concrete Formwork,LVL Joists,LVL bearers,LVL Walers,LVL Soldires and Supports.

It is storng,lightweight,straight and uniform which will reduce forming costs and improve the quality of concrete finish.

High quality full pine LVL, full pine LVL, Commercial Plywood Supplier, Manufacturer.

We are one of full pine LVL Supplier, we provide high quality LVL Plywood.

Certificates: CE 、FSC、 BSI-benchmark AS/NZS 4357.0 Australia standard Certified lvl beam

|

serial number

|

Grade

|

Tree species

|

glue

|

Product Name

|

Specification (thickness * width)mm

|

|

1

|

F17

|

Larch

|

Phenolic glue

|

LVL

|

45/65*95

|

|

2

|

F14

|

Larch Eucalyptus

|

Phenolic glue

|

LVL

|

45/65*95

|

|

Larch Pinus radiata mixture

|

Phenolic glue

|

LVL

|

45/65*95

|

|

Larch Masson Pine mixture

|

Phenolic glue

|

LVL

|

45/65*95

|

|

Pinus massoniana (medium long board)

|

Phenolic glue

|

LVL

|

45/65*95

|

|

3

|

F11

|

Pinus massoniana (short and medium board)

|

Phenolic glue

|

LVL

|

45/65*95

|

PRODUCTS SHOW

SIZE:3600*95*65(TEXTURE-OF MATERIAL:LARCH+REDIATA PINE)

Elastic modulus:F14 E12

Structural laminated veneer lumber

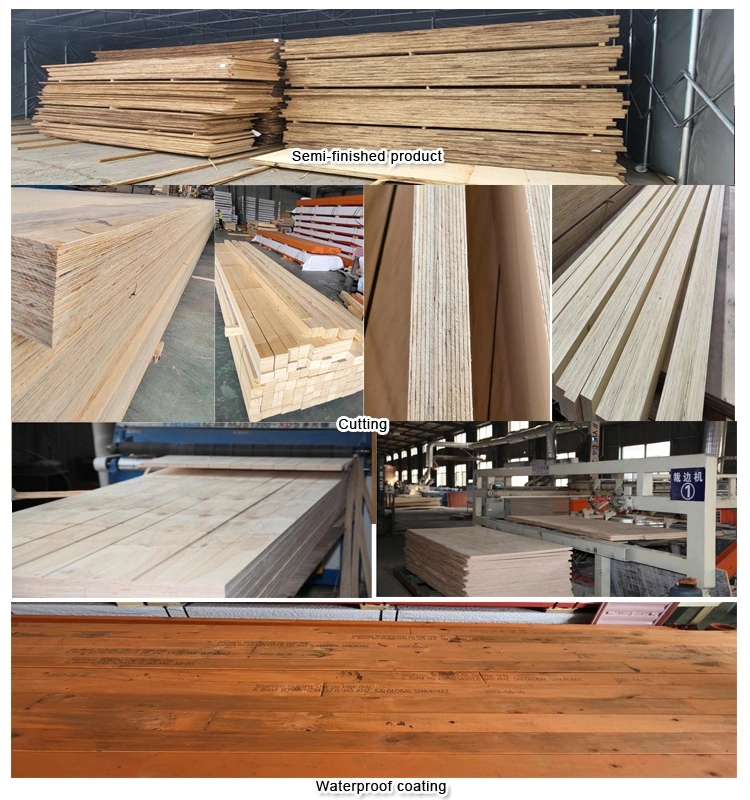

Brief introduction of our production process

Raw materials (imported Larch, Radiata pine)->Core board selection and grading

->Air-drying of the core board->Various ways to hot press drying->Raw material warehouse

->Cold pressing->Hot pressing->Semi-finished product->Cutting->Waterproof coating

PRODUCTS PACKING

FAQ

1. who are we?

We are based in Shandong, China, start from 2012,sell to South Asia(35.00%),South America(15.00%),North

America(10.00%),Africa(10.00%),Southeast Asia(5.00%),Western Europe(5.00%),Eastern Asia(5.00%),Mid

East(5.00%),Oceania(5.00%),Eastern Europe(5.00%). There are total about 201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

plywood,OSB,Film faced plywood,MDF

4. why should you buy from us not from other suppliers?

We acquired AEO, F17, BPS and Independent Intellectual Property Rights, and 5 patents related OSB product.

2production lines of OSB and 6 plywood lines. Annual exporting volume around 300000 M3.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DAF;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union;

Language Spoken:English,Chinese,Arabic,Russian

Another name:

structural laminated veneer lumber

laminated structural lumber

laminated veneer lumber dimensions

laminated veneer lumber manufacturers

lvl laminated veneer lumber

structural laminated veneer lumber(LVL)Information understanding

Laminated veneer lumber (LVL) is a material made of thick veneers laminated along the grain direction, hot pressed and glued, and then sawed.

Compared with solid wood, LVL has the advantages of uniform structure, high strength and good dimensional stability, which can meet the application requirements of wood structure building, bridge, furniture and transportation.

Main species: Masson pine laminated veneer, eucalyptus laminated veneer, Yunnan pine laminated veneer, Larch laminated veneer, poplar laminated veneer, bamboo bundle laminated veneer, bamboo and wood composite laminated veneer.

structural laminated veneer lumber (LVL) feature

laminated wood beam(lvl beam) has strong vibration resistance and vibration reduction performance, can resist fatigue failure caused by periodic stress, and can be used as structural material. The processing of laminated wood beam is as convenient as wood, which can be sawed, planed, gouged, tenon and nail, etc. Due to its special production method, the size of this material can not be limited by the size of logs or veneer specifications, fully meet the needs of large span beams and vehicles and ships, and the size of flexible, can be freely selected.

Pine LVL Beam is a high performance more sustainable alternative to lumber, headers and columns are used in structural applications to carry heavy loads with minimum weight, manufactured in a controlled environment resulting in straighter, stronger and more uniform product compared to milled lumber, creating a more stable and reliable product than dimensional umber because it doesn’t twist and warp or shrink over time.

|